One Single Quality Standard

Our staff of engineers, architects, technicians and inspectors lend their range of specialties and deep expertise to each industry, inspecting, identifying and analyzing failures in order to help represent our clients well and help build new, better, more efficient, and safer systems.

WHAT WE DO

Mechanical Engineering: Plumbing and HVAC

We determine the truth about your systems, and we’ll be with you every step of the way to help resolve your plumbing and HVAC issues.

Architecture

We offer investigation, analysis and remediation solutions for existing buildings and to develop remedial measures for construction-related problems.

Structural Engineering

Our structural experts have extensive practical and consulting experience in cranes, buildings, bridges, industrial structures, temporary structures used in construction, and other special structures.

Materials and Corrosion Engineering

Our experts specialize in metallurgy, welding (evaluation, procedures, and certifications), polymers, corrosion, ceramics, and coatings.

Mechanical Engineering: Machine Design and Analysis

Our mechanical engineers identify failure mechanisms, as well as inspect and design mechanical systems and products.

Welding Engineering

Our multidisciplinary team of professional metallurgical, mechanical, welding, corrosion, structural engineers (PEs) and inspectors are what sets us apart.

Ready to Collaborate on Your Next Project?

News and Insights

Follow our latest news and thoughts which focuses exclusively on

our insights, events, and industry trends

- Bradley Capatch, P.E.

- July 2021

- Case Study

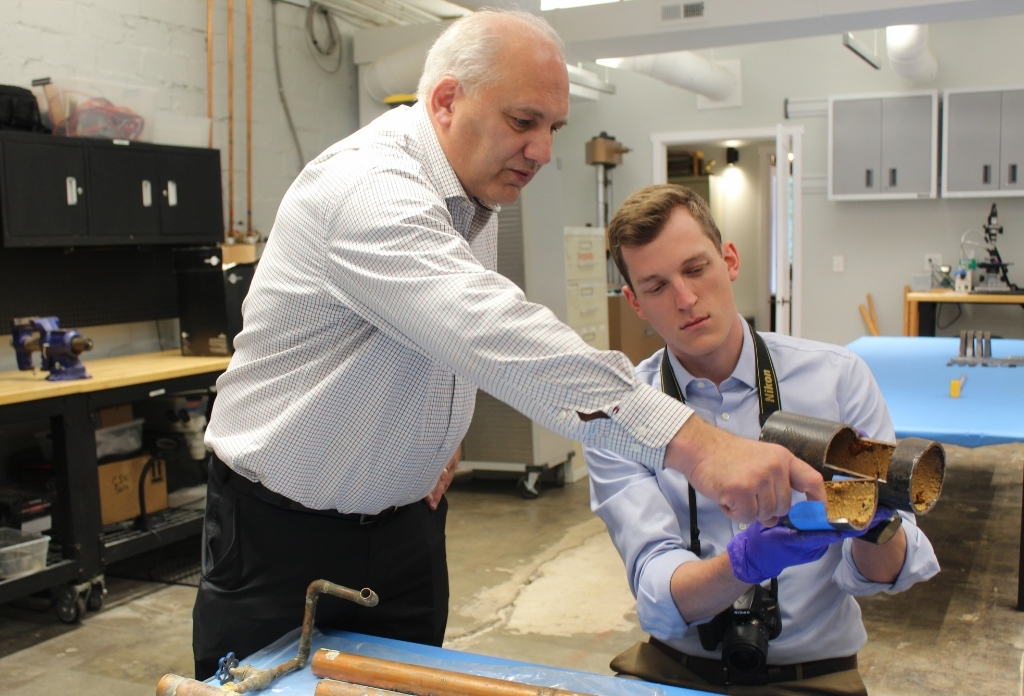

Case Study: Evaluation of Degradation in Pipes and Fittings

This case study is on the evaluation of the type of degradation in the pipes and fittings for a condominium in Seattle, Washington.

- Michael Leach, MS, P.E.

- July 2021

- Case Study

Case Study: Design and Load Test Concrete Washout Pans

In this case study, a concrete construction service hired Kent Engineering (KE) to design and load test concrete washout pans.

- Michael Leach, MS, P.E.

- July 2021

- Case Study

Case Study: Testing for a New Welding Procedure Specification (WPS)

A welding company contacted Kent Engineering (KE) to perform testing for a new Welding Procedure Specification (WPS).

- Randy Kent, MS, P.E.

- June 2020

- Case Study

Case Study: Broken Saddle Adapter for a Lifting-Jack

Our case study involves forensics and litigation support through an independent analysis of the failed saddle adaptor for a lifting-jack.