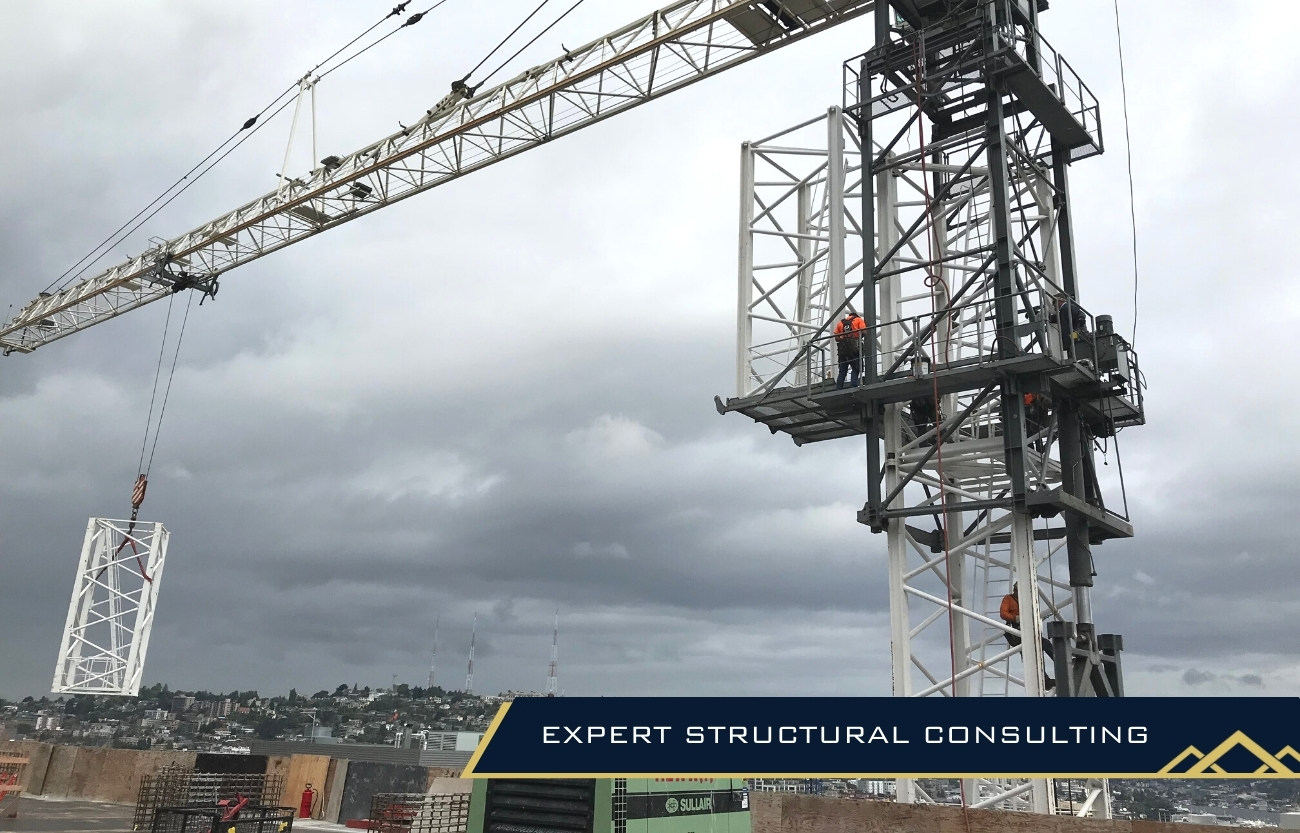

Experts in All Things Structural

Our structural experts are licensed Professional Engineers and Structural Engineers with expertise in most building and construction types, shoring, reshoring, construction engineering support, cranes, lift equipment, elevators, and bridges. We exist to answer our clients most important questions and solve their most important problems.

Why Kent Crane and Kent Engineering?

Our core belief is “Truth brings light”, therefore we rigorously pursue the truth with our inspection, engineering and architectural expertise. Our team shares this belief and is committed providing our client with truthful, objective, data driven, and practical solutions. We are a multidisciplinary team of seasoned structural, mechanical, materials, corrosion, and welding engineers, architects, and inspectors. We pride ourselves on effective communication, our science-based approach, practical solutions, and commitment to working closely with our clients, ensuring they are fully satisfied with our work.

Types of Structures

- Multifamily

- Commercial

- Cranes and Heavy Equipment

- Material Handling Equipment

- Maritime Structures

- Agricultural Structures

- Dams

- Communication and Utilities

About Us

Our team is our advantage. Our support team of expert mechanical, structural, materials, metallurgical, corrosion, welding engineers, architects and inspectors sets us apart. We pride ourselves on effective communication, and we work closely with our clients every step of the way to ensure they are fully satisfied with the answers and solutions we provide.

Our Capabilities

- Construction support services

- Life expectancy assessment and reserve study support

- Structural health monitoring

- Investigation/assessment and repair

- Root-cause failure analysis

- New design and permit support

- Design modification

- Complex design review

- Structural special inspection for anchor bolts, welding, bolting, reinforcing steel, concrete, steel, and piles

- Engineering management and consulting

Our Specializations

- Tower crane and construction hoist foundations systems and tie-ins

- Scaffolding and other construction platforms

- Plumbing/HVAC systems

- Post Tensioned Concrete: Design, Evaluation, and Repair

- Precast concrete cladding and stair

- Temporary and permanent shoring walls, deep foundation design and installation

- Seismic upgrade evaluation, design, and construction support

- Finite element analysis

- Telecommunication structures such as antenna towers, roof top screen-walls and equipment platforms

- Storage silos, tanks, and biomass steel binWind engineering

- Site Structures: Retaining Walls & Detention Vaults

- Synchronized lift and jacking capabilities for heavy structures and bridge systems

Pursuing the Truth Through Humility and Service Since 1983!

Serving Clients Across a Variety of Industries

At Kent Crane and Kent Engineering, we provide inspection, engineering and architectural services across a variety of industries, including manufacturing, transportation, construction, heavy equipment and machinery, refineries and maritime.

Our staff of inspectors, engineers and architects lend their range of specialties and deep expertise to each industry, inspecting and identifying failures in order to help represent our clients well and help build new, better, more efficient, and safer systems.

News and Insights

Follow our latest news and thoughts which focuses exclusively on

our insights, events, and industry trends

- Bradley Capatch, P.E.

- July 2021

- Case Study

This case study is on the evaluation of the type of degradation in the pipes and fittings for a condominium in Seattle, Washington.

- Michael Leach, MS, P.E.

- July 2021

- Case Study

In this case study, a concrete construction service hired Kent Engineering (KE) to design and load test concrete washout pans.

- Michael Leach, MS, P.E.

- July 2021

- Case Study

A welding company contacted Kent Engineering (KE) to perform testing for a new Welding Procedure Specification (WPS).

- Randy Kent, MS, P.E.

- June 2020

- Case Study

Our case study involves forensics and litigation support through an independent analysis of the failed saddle adaptor for a lifting-jack.