Industrial Processes

At Kent Inspection & Engineering, our team of multidisciplinary engineers specialize in the performance and optimization of varies types of industrial processes. Our team has extensive experience enhancing industrial processes by leveraging their technical expertise, problem-solving skills, and innovation mindset to drive improvements in productivity, efficiency, quality, safety, and sustainability.

Here are several ways we can enhance industrial processes:

Process Optimization: Analyze existing industrial processes to identify inefficiencies, bottlenecks, and areas for improvement. Use engineering principles and techniques such as modeling, simulation, and data analysis to optimize processes for increased productivity, efficiency, and cost-effectiveness.

Equipment Design and Innovation: Design and innovate equipment, machinery, and tools used in industrial processes to enhance performance, reliability, and efficiency.

Quality Assurance and Control: Develop and implement quality assurance and control measures to ensure that products and processes meet regulatory standards and customer requirements. Design inspection protocols, testing procedures, and quality management systems to identify and address defects, deviations, and non-conformities.

Safety and Risk Management: Safety and risk management by conducting risk assessments, hazard analyses, safety audits, design safety systems, implement safety protocols, and provide training to mitigate risks and prevent accidents, injuries, and environmental incidents.

Process Maintenance: Develop predictive maintenance strategies to ensure the reliability, detect equipment failures, anticipate maintenance needs, and optimize maintenance schedules, minimizing downtime and maximizing productivity.

Continuous Improvement: Foster a culture of continuous improvement by implementing lean manufacturing principles.

About Us

Our team is our advantage. Our support team of expert mechanical, structural, materials, metallurgical, corrosion, welding engineers, and inspectors sets us apart. We pride ourselves on effective communication, and we work closely with our clients every step of the way to ensure they are fully satisfied with the answers and solutions we provide.

Types of Industrial Processes we serve:

Manufacturing Processes:

- Machining

- Casting and Molding

- Forming and Joining (forging, stamping, bending, welding, soldering)

- Assembly

- Additive Manufacturing (3D Printing)

- Chemical Processing

- Textile Manufacturing

Energy Production Processes:

- Power Generation

- Oil Refining

- Renewable Energy

Chemical and Petrochemical Processes:

- Fertilizer Production

- Polymer Production

- Petrochemical Refining

Food and Beverage Processing:

- Food Processing

- Beverage Production

Mining and Mineral Processing:

- Mining

- Mineral Processing

Environmental and Waste Management Processes:

- Water Treatment

- Waste Management

Experts and Associates

Founder and principal of Kent Engineering, Randy Kent is a Registered Professional Engineer with over 37 years of experience in failure analysis and mechanical engineering forensics. Randy holds a bachelor’s degree and master’s degree in in metallurgical engineering, both from the University of Washington.

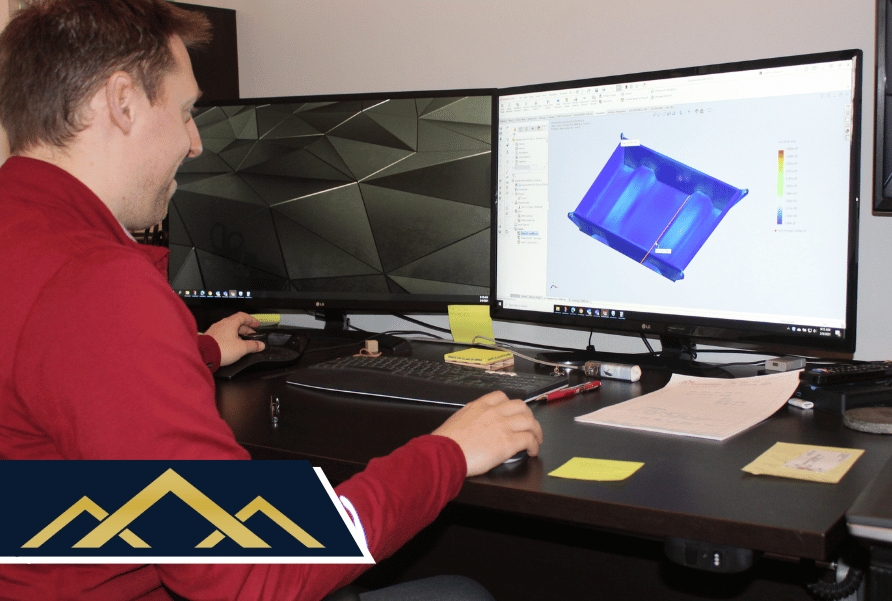

Michael is a welding engineer and project manager, receiving his Bachelor’s degree from North Dakota State University and completed his Masters in Mechanical Engineering from University of Washington. He is a certified welding engineer (CWEng), certified welding inspector (CWI) and an ASNT Level II Visual Inspector. He is also a certified Solidworks Professional.

Pursuing the Truth Through Humility and Service Since 1983!

Serving Clients Across a Variety of Industries

At Kent Inspection & Engineering, we provide inspection and engineering across a variety of industries, including manufacturing, transportation, construction, heavy equipment and machinery, refineries and maritime.

Our staff of inspectors and engineers lend their range of specialties and deep expertise to each industry, inspecting and identifying failures in order to help represent our clients well and help build new, better, more efficient, and safer systems.

News and Insights

Follow our latest news and thoughts which focuses exclusively on

our insights, events, and industry trends

- Michael Leach, MS, P.E.

- March 2025

- Careers

We are seeking a motivated full-time structural engineer to be a member of our team. We are looking for a structural engineer who will be able to communicate with clients, construct budgets/proposals, manage projects and complete projects on their own or within a team.

- Michael Leach, MS, P.E.

- July 2021

- Case Study

In this case study, a concrete construction service hired Kent Engineering (KE) to design and load test concrete washout pans.

- Michael Leach, MS, P.E.

- July 2021

- Case Study

A welding company contacted Kent Engineering (KE) to perform testing for a new Welding Procedure Specification (WPS).

- Randy Kent, MS, P.E.

- June 2020

- Case Study

Our case study involves forensics and litigation support through an independent analysis of the failed saddle adaptor for a lifting-jack.