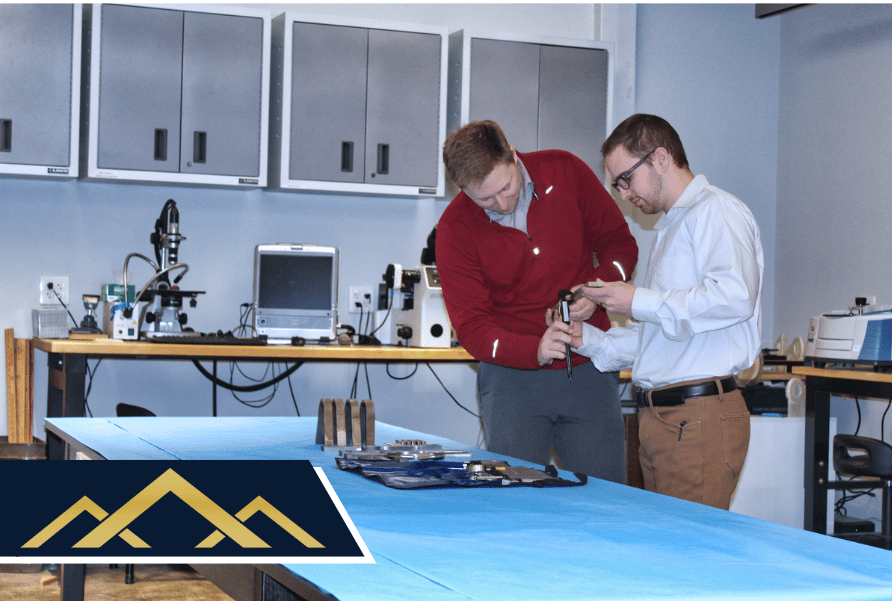

Elevating Welding Excellence with Precision, Compliance, and Safety

At Kent Inspection & Engineering we understand that in the world of welding, precision, compliance, and safety are paramount. With our comprehensive range of services, we are committed to helping you achieve excellence in welding processes while ensuring full compliance with industry standards and regulations.

We bring a wealth of experience and expertise to the table. Our team consists of professional engineers (P.E.), certified welding engineer (CWEng) and certified weld inspectors (CWI), and technicians who are dedicated to delivering top-tier services.

We are well-versed in various welding processes, including:

- Gas Metal Arc Welding (GMAW/MIG)

- Shielded Metal Arc Welding (SMAW/Stick)

- Gas Tungsten Arc Welding (GTAW/TIG)

- Flux-Cored Arc Welding (FCAW)

- Submerged Arc Welding (SAW)

- And many more

About Us

Our team is our advantage. Our support team of expert mechanical, structural, materials, metallurgical, corrosion, welding engineers, and inspectors sets us apart. We pride ourselves on effective communication, and we work closely with our clients every step of the way to ensure they are fully satisfied with the answers and solutions we provide.

Capabilities:

Procedure Qualification

- Develop and qualify welding procedures to meet industry standards and codes.

- Ensure your welding processes are efficient and produce high-quality results.

- Facilitate documentation and certification for regulatory compliance.

Welder Qualification

- Verify the skills and capabilities of your welding personnel.

- Ensure welders are qualified for specific procedures and materials.

- Maintain a qualified workforce through periodic testing.

Weld Inspection and Testing

- Non-destructive testing (NDT)

- Destructive testing (DT)

- Quality control and quality assurance inspections.

Benefits of Weld Procedure Testing and Qualification

- Improved Welding Quality: Ensure that your welding processes produce consistent, high-quality welds that meet industry standards.

- Cost Reduction: Minimize rework, scrap, and downtime by identifying and rectifying issues early in the welding process.

- Compliance: Stay in compliance with industry regulations and codes, reducing the risk of costly penalties and legal liabilities.

- Enhanced Reputation: Build trust with clients and stakeholders by demonstrating your commitment to quality and safety.

Experts and Associates

Michael is a welding engineer and project manager, receiving his Bachelor’s degree from North Dakota State University and completed his Masters in Mechanical Engineering from University of Washington. He is a certified welding engineer (CWEng), certified welding inspector (CWI) and an ASNT Level II Visual Inspector. He is also a certified Solidworks Professional.

Ben is a mechanical engineer focusing his efforts on crane and hoist systems. He is also a certified weld inspector. Ben received his Bachelor’s degree in mechanical engineering from Seattle University. Since graduating, he has spent his career working for Kent Crane gaining experience in crane inspections, weld inspections and related engineering.

Pursuing the Truth Through Humility and Service Since 1983!

Serving Clients Across a Variety of Industries

At Kent Inspection & Engineering, we provide inspection and engineering across a variety of industries, including manufacturing, transportation, construction, heavy equipment and machinery, refineries and maritime.

Our staff of inspectors and engineers lend their range of specialties and deep expertise to each industry, inspecting and identifying failures in order to help represent our clients well and help build new, better, more efficient, and safer systems.

News and Insights

Follow our latest news and thoughts which focuses exclusively on

our insights, events, and industry trends

- Michael Leach, MS, P.E.

- July 2021

- Case Study

In this case study, a concrete construction service hired Kent Engineering (KE) to design and load test concrete washout pans.

- Michael Leach, MS, P.E.

- July 2021

- Case Study

A welding company contacted Kent Engineering (KE) to perform testing for a new Welding Procedure Specification (WPS).

- Randy Kent, MS, P.E.

- June 2020

- Case Study

Our case study involves forensics and litigation support through an independent analysis of the failed saddle adaptor for a lifting-jack.